P2 Section #2 | Automotive Maintenance - Pg 4

Section 2 | Other Automotive Fluids

Revised On: Feb. 25, 2024 - 9:00 a.m.

Learning Objectives:

- Identify and find sources of other automotive fluids and harmful pollutants.

- Identify the impact of other automotive fluids on the environment and human health.

- Minimize waste of other automotive fluids through best management practices.

- Determine additional P2 opportunities to reduce other automotive fluids waste.

Other Automotive Fluids

We’ve covered oils and solvents, but there are a couple more common and harmful fluids that you’ll encounter when working with vehicles. This short lesson will cover what to consider when completing motor vehicle maintenance or maintaining coolant.

Refrigerants

Refrigerants are fluids used to transfer heat in an air conditioning system. They often change phases from gas to liquid as they move through the system. Refrigerants are gasses readily released into the air under normal pressures and temperatures. Let’s first review the types of refrigerants used in vehicles and may come across in your workplace.

Two major categories of refrigerants in vehicle air conditioning systems are chlorofluorocarbons (CFC) and hydrofluorocarbons (HFC). The refrigerant most commonly used in the automotive industry was CFC-12, commercially known as Freon. This refrigerant has been banned since 1994 by the EPA, but there can still be cars brought in for maintenance made before 1994 that need to be retrofitted to have newer refrigerant systems. Car models up until model year 2021 will likely have HFC-134a, which is a hydrofluorocarbon refrigerant. HFC-134a was the main alternative to CFC-12 when phasing out the more harmful chlorofluorocarbon refrigerant. HFC-134a is now listed as unacceptable in cars sold and manufactured in the US. The EPA’s Significant New Alternatives Policy Program reviewed and listed alternatives for MVAC systems. These alternatives included HFC-152a, HFO-1234yf and CO2 (R-744). HFO-1234yf is a newer category of refrigerant and is still emerging.

HFC-134a and CFC-12 are considered to have low toxicity. When overexposed to these refrigerants, which can occur in enclosed spaces that are not well-ventilated, some key symptoms can occur:

- Inhalation can cause dizziness, tremors, asphyxiation, unconsciousness, irregular heartbeat, and even cardiac arrest.

- Eye irritation

- If skin contact occurs with the refrigerants as a liquid, frostbite can occur.

Always review the SDS for any other health considerations and PPE requirements that come with the specific product you are using.

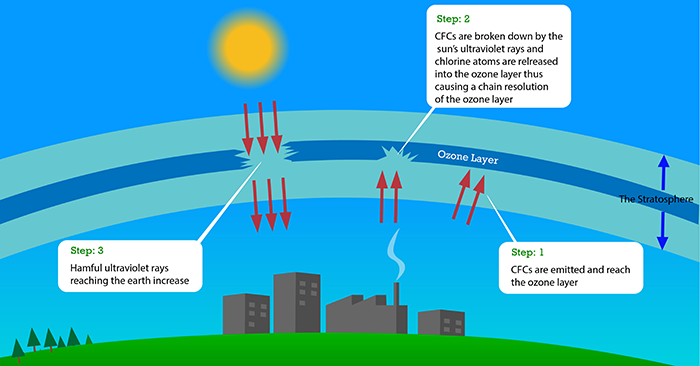

The key impact of CFC refrigerant releases is ozone layer depletion, but what is ozone depletion? The ozone layer is a layer in our atmosphere mainly responsible for absorbing harmful Ultraviolet B (UVB) rays produced by the sun. As the EPA states, UVB rays cause various skin issues, such as sunburn and cancer. It can also lower your body’s ability to fight illness. UV light that reacts with CFCs breaks down the substance to release chlorine into our atmosphere. Chlorine then goes on to destroy ozone molecules. Unlike ozone, which we touched on in the solvent section, atmospheric ozone benefits the environment and human health.

HFC refrigerants do not share the same ozone depletion concerns as CFCs, but are considered greenhouse gasses and have high global warming potentials. Global warming potential (GWP), as defined by the EPA, is a measure of how much energy the emissions of 1 ton of gas will absorb over a given period of time relative to the emissions of 1 ton of CO2. This means that CO2 has a GWP of 1. CFC-12 and HFC-134a have a GWP of 10,900 and 1,430, respectively.1 These are both substantially higher than that of CO2, so small amounts of either substance being released into the air carry a much greater environmental impact.

Regulations have been created to address the release and handling of these refrigerants. Section 608 of the Clean Air Act (CAA) prohibits intentionally venting CFCs and their substitutes while maintaining, servicing, or disposing of air-conditioning equipment. Venting in this case, would mean the release of the refrigerants into the atmosphere. Section 609 of the CAA focuses on motor vehicle air conditioning (MVAC). This section includes various requirements for working with MVAC and managing the resulting waste, such as technician certification, approved equipment, disposal requirements, and recordkeeping | See MVAC Resources >

Antifreeze

Antifreeze is a part of automotive coolant, usually a 50/50 mix of water and an antifreeze chemical. The most common antifreeze options today are ethylene glycol or propylene glycol. Antifreeze is used for precisely the same reasons as the name suggests. It reduces the freezing point of water so it does not freeze and expand within the cooling system.

- Ethylene glycol can cause the following symptoms:

- Irritation in the nose and throat through inhalation of vapors

- Irritation of eyes and skin through contact

Dizziness, headache, slurred speech, drowsiness, loss of consciousness, coma, seizures, and multi-system organ failure, depending on levels of ingestion.

Propylene glycol is generally considered a safe chemical and much less toxic than ethylene glycol. Review the SDS for your specific coolant to determine applicable health and safety considerations.

When ethylene glycol enters the environment, it does not persist and will readily biodegrade. Environmental concerns for ethylene glycol releases are from significant releases with high concentrations. Due to its toxicity, this can adversely affect wildlife that comes into contact with or ingests the substance. Propylene glycol also does not persist and will readily biodegrade in the environment. It is important to note that, much like used oil, coolant can become contaminated with heavy metals over time and can become a hazardous waste.

Antifreeze recycling on-site or through an off-site service is a worthwhile consideration for your waste. On-site recycling has a more expensive startup cost but can save considerable cost as antifreeze can be reused indefinitely. In either case, the amount of recycled antifreeze directly reduces the demand for new supplies. This creates an overall benefit for the environment as it is less harmful to process and reuse the antifreeze than to manufacture it.

P2 Opportunities

These fluids present a difficult scenario for reducing waste. They are necessary for the systems they are used in, and few alternatives require modifications to the systems themselves. P2 opportunities for refrigerant and antifreeze primarily come from properly managing and disposing of these wastes.

- Substitution of ethylene glycol with propylene glycol. Propylene glycol's lower toxicity reduces the harm involved when working with antifreeze and managing waste.

- Spill and leak prevention during maintenance. Ensure that all the proper tools and equipment are prepared appropriately when completing any coolant or refrigeration service. Consult with customers to fully repair leaking systems. If a leak is detected in refrigerants, immediately evacuate all of the existing refrigerants to prevent further releases. Regarding antifreeze, ensure that any drain pans are in the appropriate position and are the correct size for the vehicle being serviced. Make sure to dispose of any drained liquids immediately to prevent accidental spills/releases.

- Work with the customer to fully repair leaking systems. If a leaking system is identified, you may not always get buy-in from the customer to complete full repairs. Always encourage customers to repair leaking systems to prevent further environmental releases once they leave the shop.

In the next lesson, we will talk about batteries and e-waste.

1 Refrigerant Transition & Environmental impacts. United States Environmental Protection Agency. (2023, April 4) | Learn More >

GUIDES

Implementing P2 > | Spanish >

Inventory Control > | Spanish >

Solvent-Contaminated Wipes >

Used Oil >

Waste Determination >

POSTERS

Clear Walkways > | Spanish >

Clean Workspace > | Spanish >

First-In, First-Out > | Spanish >

Use & Stow > | Spanish >

VIDEOS

Auto Shop Housekeeping>

FIFO for Auto Shops >

What is P2 >

OTHER

P2 in Action >